Four chuck automatic loading and unloading pipe laser cutting machine; It is the perfect combination of optical, mechanical, electrical, and control technologies in industrial applications; It mainly consists of fiber laser, laser cutting head, fully functional CNC system, machine tool host, transmission device, pneumatic system, pneumatic chuck, dust removal system, oil circulation system, water cooling system, etc.

1 Year Warranty

Lifetime Warranty

Free Technical Consult for Life

This model is a fully automatic laser cutting machine for feeding pipes. It adds a loading and unloading mechanism to the ordinary pipe laser cutting machine, which can achieve automatic cutting of pipes in batches without human intervention

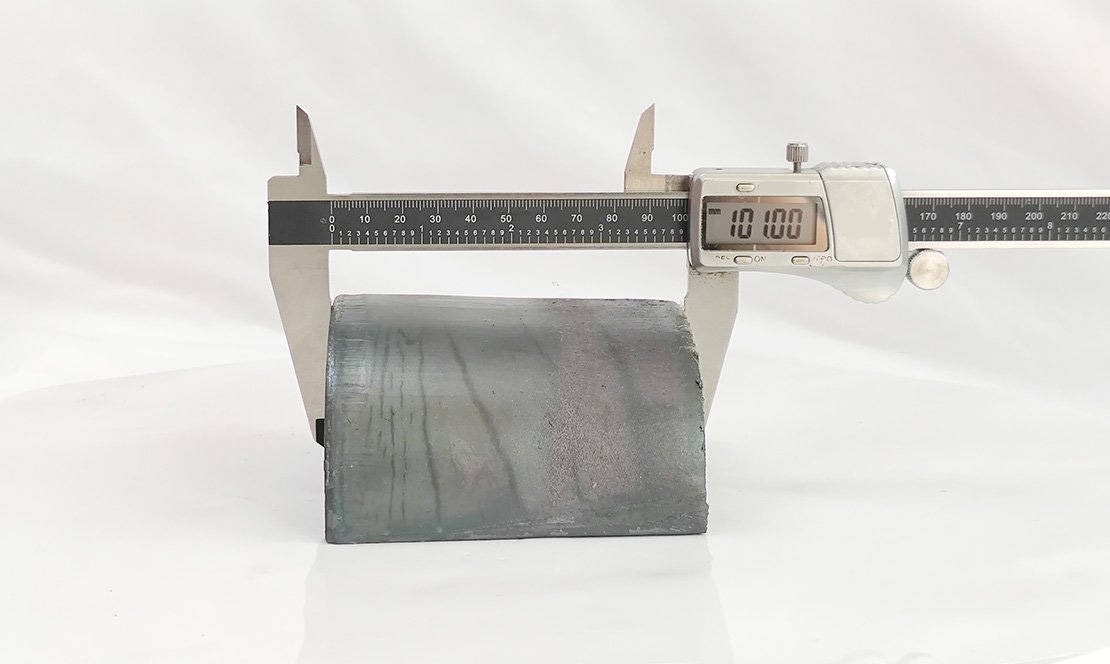

The feeding diameter is 20-220mm, the length is 6m, the hopper can bear 4t, and the maximum weight of a single pipe is 380kg. The first feeding takes about 35s, and the cycle feeding takes about 15s.

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

It can achieve the function of setting groove cutting for pipes, with diverse cutting options and improved functionality, providing customers with more powerful cutting equipment and enhancing competitiveness.

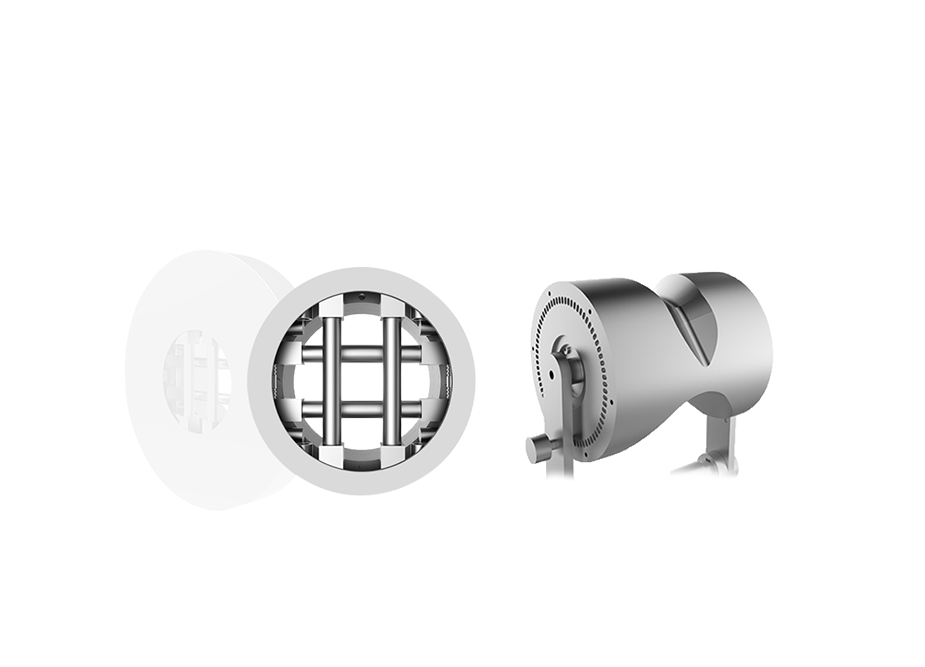

Motor driven, with electric chuck clamping design for front and rear, automatic center adjustment, wide clamping range, simple and stable operation

Gear transmission method, higher transmission efficiency

Intelligent pipe cutting design, solving deformation problems during long pipe cutting operation, effectively ensuring support stability

Fuji servo motor, as a world-class motor manufacturer, enjoys a high reputation in motion control. Winning market praise in the industry and receiving high recognition from customers

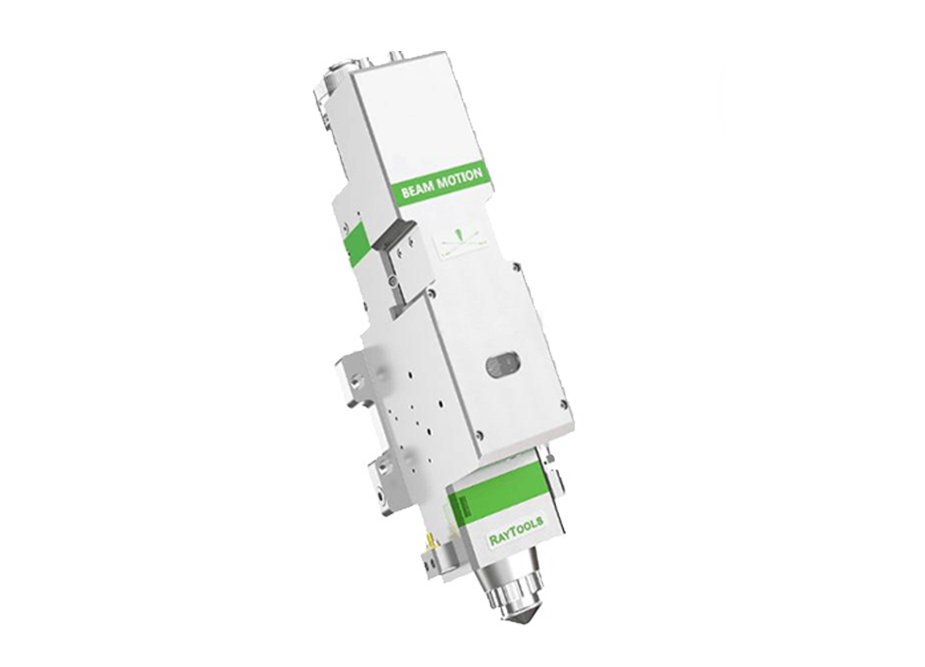

Fully upgraded dust-proof design, double-layer protection, and extremely high risk of contamination of the collimating lens when inserting and removing optical fibers. The new laser head adds an upper protective mirror to the collimation component, minimizing the risk of collimation mirror contamination. At the same time, the structure of the protective mirror has been comprehensively upgraded, and a dust cover has been added to the protective mirror. The double-layer protection design greatly improves the user experience of replacing protective lenses, and the risk of lens contamination is almost zero;

Professional intelligent control system with automatic nesting function

Stable performance, fast operation, supports multiple common file formats, DXF, PLT

A concise and fast operating system, one click import of multiple types of cutting graphics, accurate cutting instructions, and a better user experience.

|

Model |

T6020HA4 |

|

Pipe processing range |

Φ20mm-360mm; □20mm~□250mm |

|

Laser Power |

3000W-12000W |

|

Reposition accuracy |

0.05mm |

|

Maximum acceleration |

0.8G |

|

Maximum speed of chuck |

75r/min |

Stainless Steel, Mild Steel, Carbon Steel, Aluminum, Copper, Brass, Bronze, Alloy Steel, Galvanized Steel, Titanium, Nickel Alloys, and more.

Manufacturing & Heavy Industry, Shipbuilding, Steel Structure Construction, Bridge Manufacturing, Aerospace, Military & Defense, New energy and Battery Manufacturing, Automotive, Medical Devices, Energy & Power Generation, Electronics, Oil & Gas, Machinery Manufacturing, HVAC (Heating, Ventilation, and Air Conditioning), Railways, and more.

The materials and industries abovementioned can benefit from our machine. For cutting solution on specific applications, welcome to contact us.

Tell us what kind of material you need to cut and how thick, and other demands, we will give you the best solution and help you succeed.