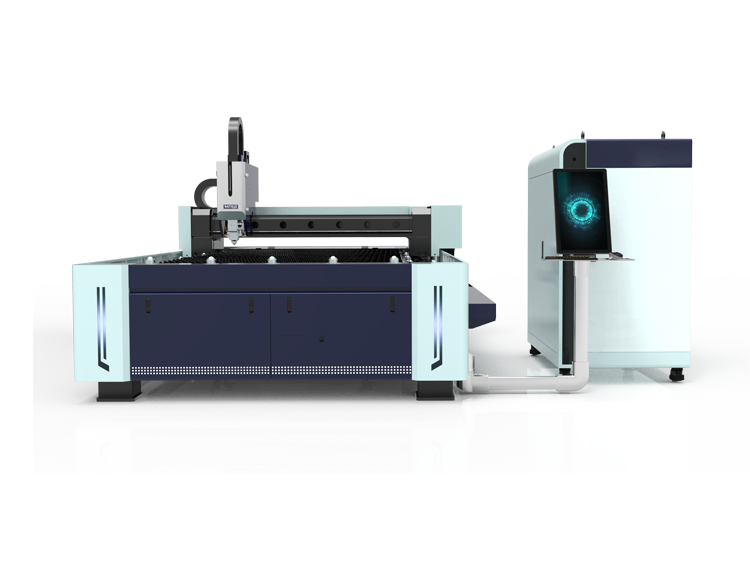

The laser is equipped with a high-precision gear rack and guide rail transmission mechanism, and is assembled into a precision CNC fiber laser cutting machine through an advanced CNC system. It is a high-tech product that integrates laser cutting, precision machinery, CNC technology and other disciplines. The machine has good dynamic performance, fast servo response, and is equipped with a medium power fiber laser to achieve high cutting efficiency. Mainly used for cutting and forming metal materials such as carbon steel plates and stainless steel plates, it is the first choice for processing metal materials. Adopting the Baichu operating system and equipped with a fiber optic dedicated CNC system - Baichu, with powerful functions, user-friendly interface, and easy to understand operation.

1 Year Warranty

Lifetime Warranty

Free Technical Consult for Life

4000W-20000W Laser Power Optional, able to cut through thicker metal sheets at a faster rate of up to 140m/min (213′/min), enabling you to achieve higher production efficiency and output in a shorter time.

Whole machine uses industry-leading servo motors, providing high positioning speed of 126m/min (413′/min) and acceleration of 0.6~1.5G, achieving faster movement and improved working efficiency.

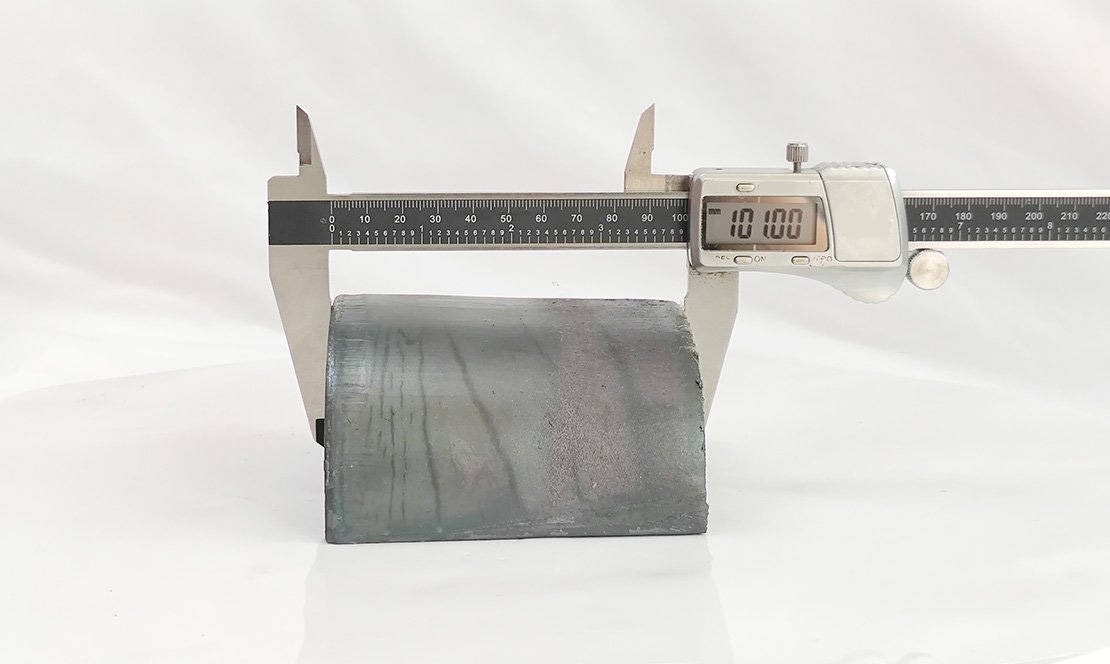

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Don’t miss out this opportunity to increase your efficiency and quality. Invest in our machine today and take your business to the next level!

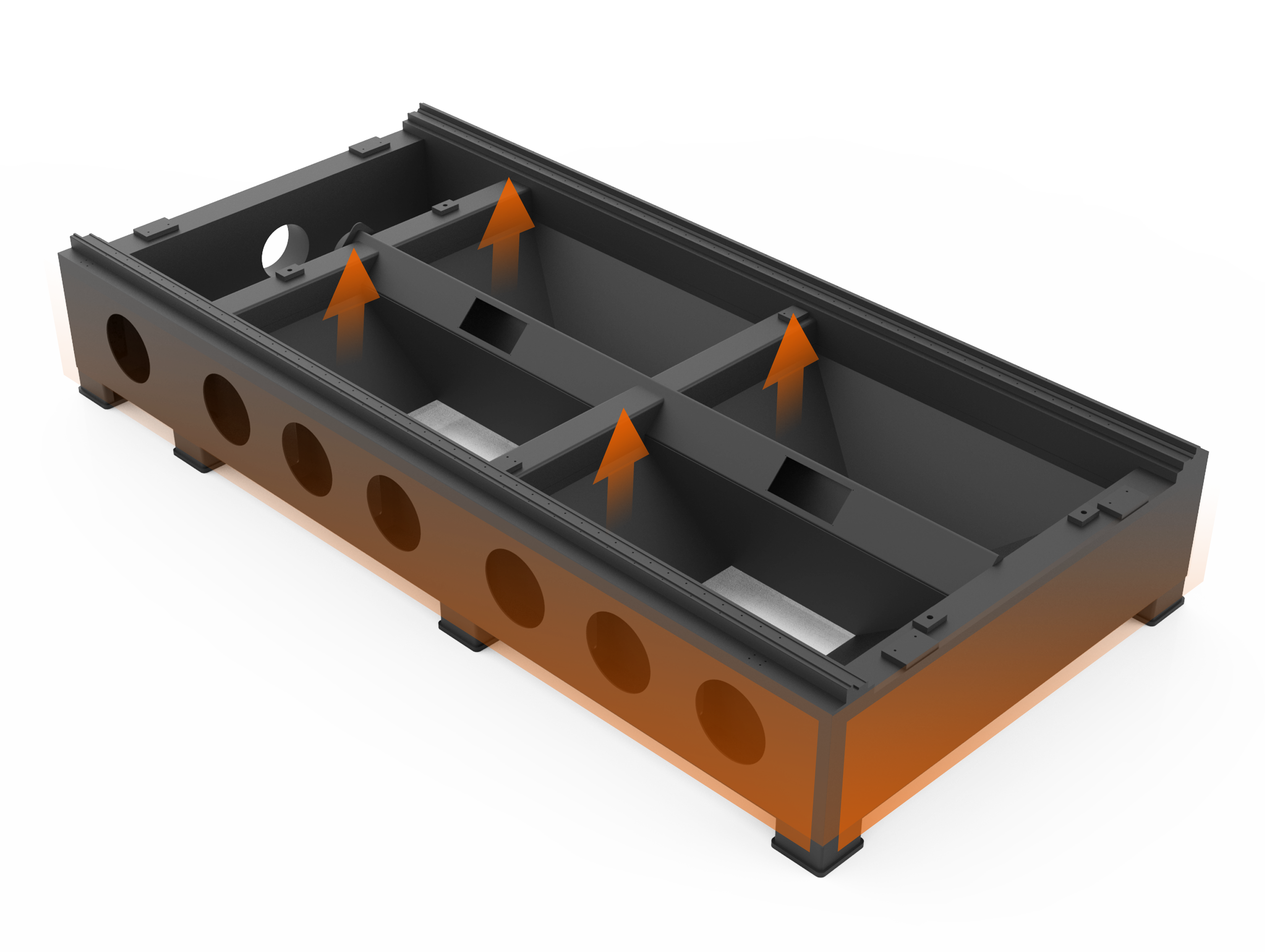

Independent innovation of hollow steel structure welding technology ensures the rigidity and stability required for high-speed movement of machine tools, while minimizing the thermal impact generated during the machining process;

The overall use of graphite board anti burning technology effectively prevents damage to the bed body caused by high power and maintains stable quality.

Compared to traditional bed frames, it has the characteristics of good shock absorption, large weight, small deformation, and lower operating costs

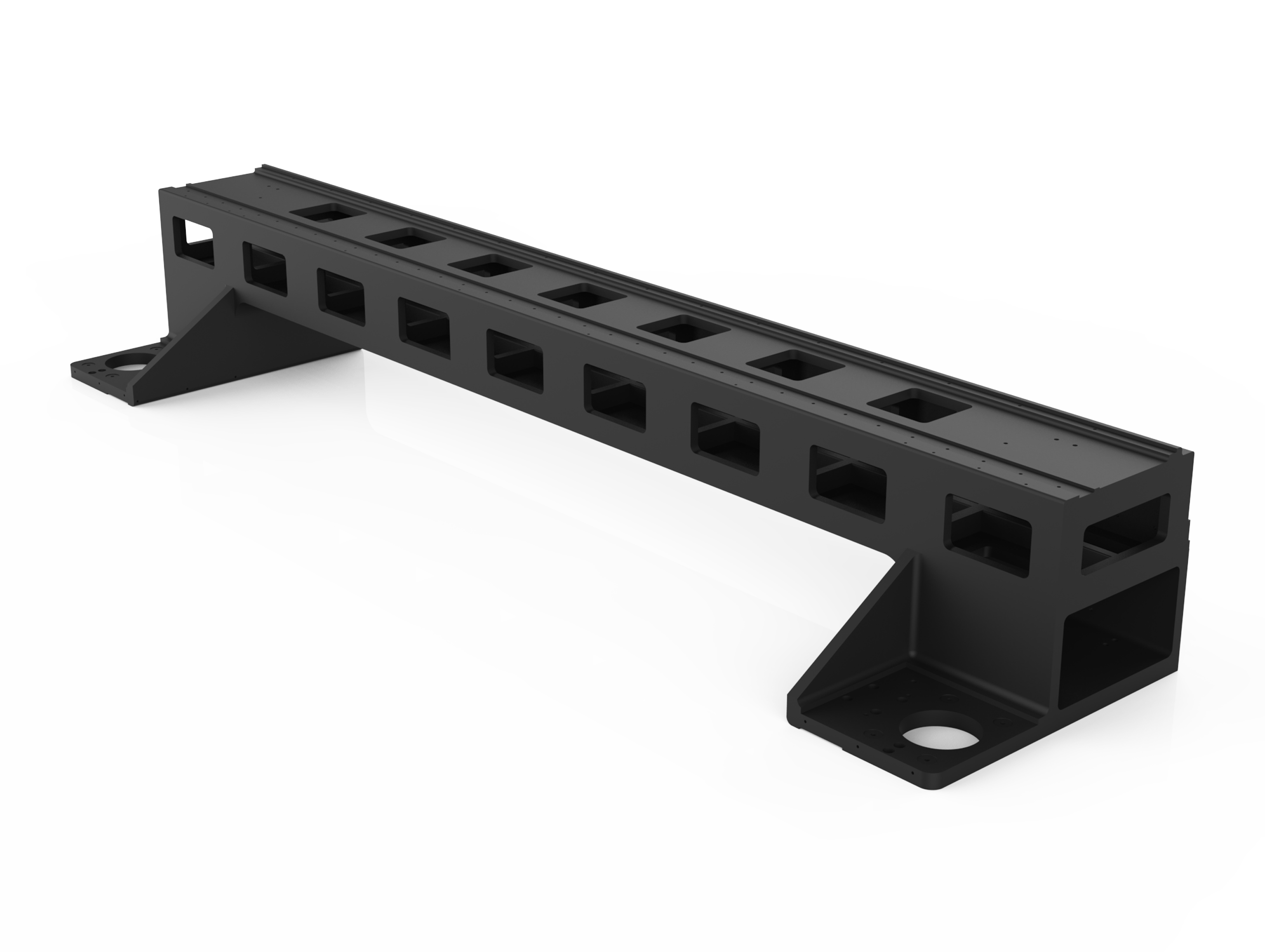

viation aluminum has sufficiently high performance indicators, with good strength, plasticity, impact toughness, fatigue performance, and weldability. More importantly, while ensuring the same performance indicators, the cast aluminum crossbeam has a lighter weight, which facilitates high-speed movement during cutting and processing. With sufficient accuracy, it can achieve rapid cutting of various shapes.

Made of high-performance manganese steel material, with high rigidity and light weight; Through special heat treatment techniques, the strong rigidity of the crossbeam during high-speed operation is enhanced, ensuring stability during the cutting process,

Clever intelligent lubrication structure design, automatic intelligent lubrication can be achieved for moving parts, reducing the load of servo motors. While saving electricity costs, the equipment has extremely high operating speed

Based on the excellent characteristics of the crossbeam, the production process can achieve faster dynamic response, flexible and precise positioning, high-precision cutting of various shapes, and provide processing efficiency.

Automatic focusing, capable of quickly changing different focal lengths to meet metal cutting needs of different thicknesses. The internal structure is completely sealed to prevent dust pollution to the optical parts;

Integrated temperature sensing technology and CNC operation compensation to avoid thermal lens effect; When the cutting head moves empty, it intelligently avoids obstacles 360 degrees to protect the cutting head;

Compared to traditional manual laser heads, it has advantages such as higher cutting accuracy, wider applicability, lower processing costs, and longer service life

The new generation of CNC system adopts a more powerful combination of functions and algorithms, supporting various cutting processes such as rotary cutting and fixed height cutting;

32 inch large color touch screen, dual monitoring function, can be matched with different lasers and dynamically adjust the duty cycle according to the cutting speed; The integrated bus CNC communication system has a response that is more than 60% higher than that of ordinary machines;

Capable of controlling the temperature and humidity inside the machine, there is no need to equip an air-conditioned room for the machine.

This achieves stable performance even during prolonged use and protects the service life of the machine and electrical components

|

Model |

F3015 |

|

Working Area |

3000*1500mm |

|

Laser Power |

1000W-1500W |

|

Positioning accuracy |

0.05mm |

|

Reposition accuracy |

0.03mm |

|

Min.line width |

0.1mm |

|

Maximum acceleration |

0.5G |

|

Maximum speed of chuck |

45m/min |

Stainless Steel, Mild Steel, Carbon Steel, Aluminum, Copper, Brass, Bronze, Alloy Steel, Galvanized Steel, Titanium, Nickel Alloys, and more.

Manufacturing & Heavy Industry, Shipbuilding, Steel Structure Construction, Bridge Manufacturing, Aerospace, Military & Defense, New energy and Battery Manufacturing, Automotive, Medical Devices, Energy & Power Generation, Electronics, Oil & Gas, Machinery Manufacturing, HVAC (Heating, Ventilation, and Air Conditioning), Railways, and more.

The materials and industries abovementioned can benefit from our machine. For cutting solution on specific applications, welcome to contact us.

Tell us what kind of material you need to cut and how thick, and other demands, we will give you the best solution and help you succeed.