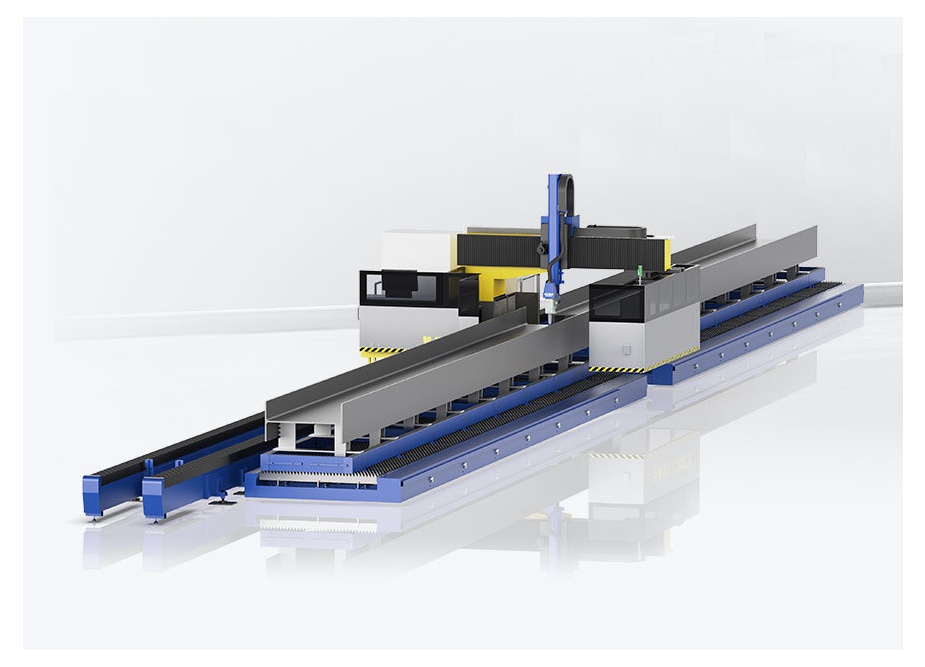

The plate and tube type integrated machine is a multifunctional machine that can simultaneously solve the cutting and cutting of materials such as H-beams, channel steels, round pipes, square pipes, angle steels, flat plates, and flat plate grooves. It can meet the functional requirements of three different types of equipment.

1 Year Warranty

Lifetime Warranty

Free Technical Consult for Life

4000W-20000W Laser Power Optional, able to cut through thicker metal sheets at a faster rate of up to 140m/min (213′/min), enabling you to achieve higher production efficiency and output in a shorter time.

Whole machine uses industry-leading servo motors, providing high positioning speed of 126m/min (413′/min) and acceleration of 0.6~1.5G, achieving faster movement and improved working efficiency.

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Support contour detection, effectively avoid size errors;

Equipped with a centering device to effectively control material deformation;

Open structure double-station design saves loading and unloading time;

Independently developed three-dimensional six-axis five-linkage technology, ultra-high efficiency;

High-precision floating shaft design, fast response;

The processing efficiency is about 15 times that of manual work;

Stable and safe structural design, 24h continuous operation.

|

Model |

H |

|

Steel cutting range |

Height B ≤ 450mm Width H ≤ 1000mm Length L≤ 26000mm (customized on demand) |

|

Laser Power |

12000w/20000w/30000w |

|

X-axis travel |

26000mm |

|

Y-axis travel |

1750mm |

|

Z axis travel |

910mm |

|

A-axis stroke (rotary axis) |

±90° |

|

C-axis stroke (rotary axis) |

±90° |

|

U axis travel (height adjustment axis) |

0- 50mm |

|

X/Y/Z maximum positioning speed |

30m/min |

|

X/Y/Z positioning accuracy |

≤ 0.1 mm |

|

Cutting accuracy |

≤ 0.5 mm |

Stainless Steel, Mild Steel, Carbon Steel, Aluminum, Copper, Brass, Bronze, Alloy Steel, Galvanized Steel, Titanium, Nickel Alloys, and more.

Manufacturing & Heavy Industry, Shipbuilding, Steel Structure Construction, Bridge Manufacturing, Aerospace, Military & Defense, New energy and Battery Manufacturing, Automotive, Medical Devices, Energy & Power Generation, Electronics, Oil & Gas, Machinery Manufacturing, HVAC (Heating, Ventilation, and Air Conditioning), Railways, and more.

The materials and industries abovementioned can benefit from our machine. For cutting solution on specific applications, welcome to contact us.

Tell us what kind of material you need to cut and how thick, and other demands, we will give you the best solution and help you succeed.